April 21, 2016 by Mike Doughty

This post is the second example of how to make a 110 volt temperature controlled soldering station. Please refer to the previous post for information on materials used, their costs and where they can be obtained. The steps for modifying the soldering iron are very similar to the previous post but a few things are different for this version.

The steps for making the controller are virtually the same. As a result, most of the details for the controller have been omitted in this post. The main difference is the addition of a green ground wire to the 4-pin female DIN socket. Continue Reading »

Posted in Projects, Shop Tools, Soldering Irons, Temperature Controllers | Tagged 110 Volt Soldering Station | 1 Comment »

October 3, 2015 by Mike Doughty

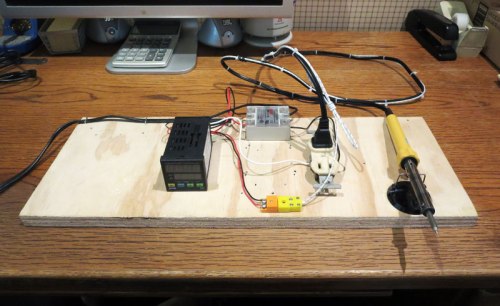

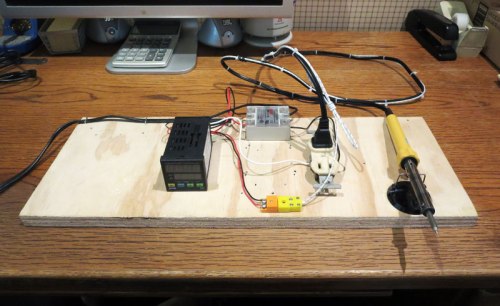

This post shows how to build a do it yourself 110 volt soldering station. It is a step by step guide that shows how to convert a regular plug-in soldering iron into a temperature controlled unit.

It is an easy project that is inexpensive to make and requires only basic skills to build. It is made from off the shelf parts that can be obtained from online suppliers plus a few parts from a local hardware store. It is inexpensive to build plus it makes a shop tool that is on par with some commercially available units. Continue Reading »

Posted in Projects, Shop Tools, Soldering Irons, Temperature Controllers | Tagged 110 Volt Soldering Station | 25 Comments »

August 27, 2015 by Mike Doughty

Here’s a quick and easy way to spot weld a thermocouple with a 12 volt car battery, a set of jumper cables, a claw hammer and a set of long nose pliers.

Thermocouple spot weld next to soldering iron

This makeshift method can be used if the thermocouple spot weld breaks off or even if you want to make a new thermocouple from wire. Continue Reading »

Posted in Soldering Irons, Temperature Controllers | Tagged Thermocouple Spot Weld | 3 Comments »

August 6, 2015 by Mike Doughty

This is a follow up post on the second version for how to modify a regular plug-in soldering iron to work with a digital temperature controller.

The goal is to find the right location for the thermocouple inside the soldering iron. Temperature readings can be affected by the smallest change in position. The location of the thermocouple is very sensitive. Continue Reading »

Posted in Soldering Irons, Temperature Controllers | Tagged Soldering Iron, Thermocouple Adjustment | Leave a Comment »

August 3, 2015 by Mike Doughty

This post shows how to add a K-type thermocouple to a 120 volt plug-in soldering iron for use with a PID temperature controller. This is a follow up to a previous post on the Soldering Iron PID Temperature Controller. Please see the previous post for more details on how to add a thermocouple to a plug-in soldering iron with a mica heating element. The method I used here was basically the same.

This second version has a few improvements. It uses a better soldering iron that gets hotter and heats up faster. The PID controller is able to work at higher temperatures than the previous version plus this version uses an SSR to switch the soldering iron on and off. The solid state relay has no mechanical parts to wear out plus it is capable of much more precise switching than a mechanical relay. Continue Reading »

Posted in Projects, Soldering Irons, Temperature Controllers | Tagged PID Temperature Controller, Soldering Iron, Thermocouple | 2 Comments »

July 12, 2015 by Mike Doughty

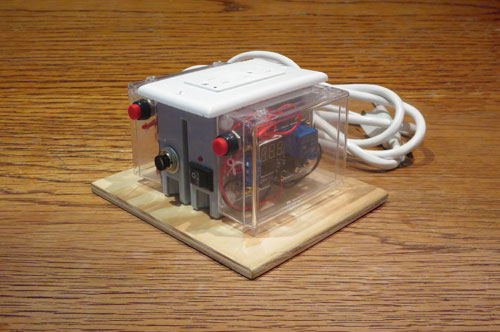

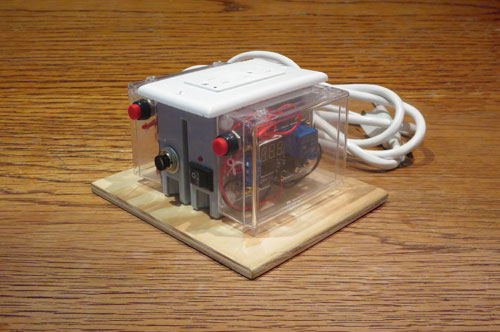

This is a do it yourself project for a digital temperature controlled soldering station. It is an easy project that requires only basic skills to build and it it is constructed entirely from off the shelf components available from online sources.

The unit uses a PID temperature controller, an SSR (Solid State Relay) and a transformer plus a metal enclosure case, a soldering stand and a few other parts. It is relatively inexpensive to build, plus it makes a pretty good shop tool. Continue Reading »

Posted in Projects, Shop Tools, Soldering Irons, Temperature Controllers | Tagged Homemade Soldering Station | 7 Comments »

June 4, 2015 by Mike Doughty

This is a follow up to a previous post on a way to get temperature control for a plug-in soldering iron without a temperature sensor. Instead of using a sensor to control the temperature, this unit sends power to the soldering iron in precisely timed pulses in a way that mimics the timing of how a temperature controlled soldering station does.

Pulse timer controller for plug-in soldering irons

Watching the LED of a high quality soldering station blink on and off while the soldering iron was maintaining stable temperature gave me the idea. It looked like it was going on and off with regularity in a rhythm. I thought, why not use a timer circuit to do something similar for a regular plug-in soldering iron? Continue Reading »

Posted in Projects, Shop Tools, Soldering Irons, Temperature Controllers | Tagged Soldering Iron, Timer Circuit | 3 Comments »

May 11, 2015 by Mike Doughty

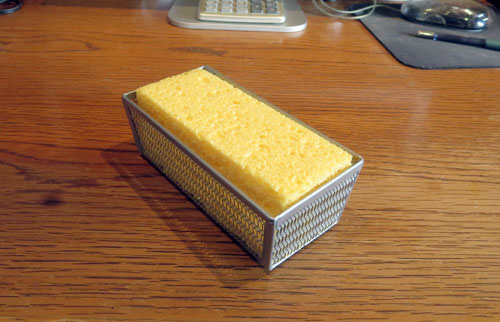

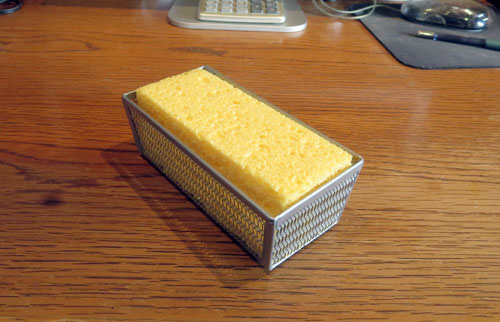

A soldering iron tip cleaning sponge is a basic soldering accessory. Many soldering iron stands even include a small rectangular cleaning sponge plus a tray in the base where it is to be housed.

The whole point of keeping the soldering iron tip clean is to protect it against wear which can lead to tip failure. Continue Reading »

Posted in Soldering Accessories, Soldering Irons | Tagged Cellulose Soldering Sponge, Soldering Iron Stands, Soldering Tip Cleaning Sponge | Leave a Comment »

May 5, 2015 by Mike Doughty

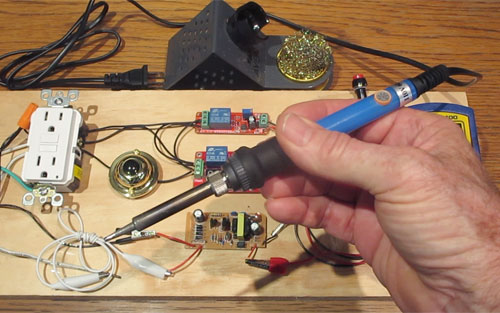

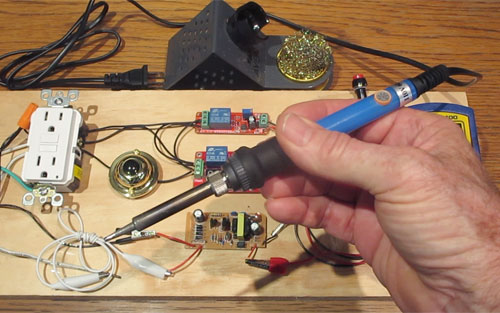

Getting precise temperature control is one of the challenges when working with a regular plug-in soldering iron. The best way to get temperature control is with a high quality soldering station but many people who work with electronics have one or more plug-in soldering irons in their toolboxes.

110v 60w soldering iron with cycle timer temperature control circuit

Although these plug-in soldering irons are considered to be good tools with much remaining useful life, they could be much better tools if a there was a reliable way to get consistent and precise temperature control from them. Continue Reading »

Posted in Projects, Soldering Irons, Temperature Controllers | Tagged Delay Timer Module, PLC Cycle Timer, Plug-in Soldering Irons | 1 Comment »

April 29, 2015 by Mike Doughty

This is a project for a do it yourself analog soldering station. The design is a variation on some low-end commercial units that don’t have a built-in temperature sensor in the soldering iron.

It’s made with a dimmer switch and a few other hardware store items. It is fairly inexpensive to make and the project can easily be completed in an evening. I needed a unit like this for some experiments I was doing with soldering irons. Continue Reading »

Posted in Projects, Soldering Irons, Temperature Controllers | Tagged Soldering Iron, Soldering Iron Dimmer Control | 5 Comments »

Older Posts »